acrylic print uv flatbed printer widely used ce approved

Specifications

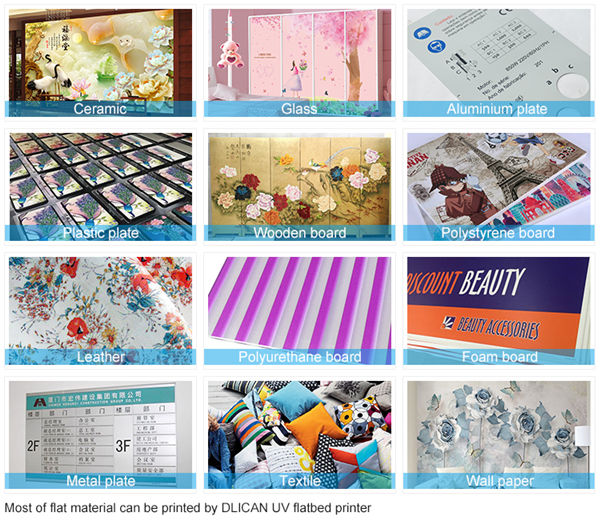

Usage: Card Printer, Cloths Printer, Label Printer, Paper Printer, Leather,Ceramic,PVC,Plastic,Metal,etc

Plate Type: Flatbed Printer

Condition: New

Dimensions(L*W*H): 4100MM*1870MM*1310MM

Weight: 1250KG

Automatic Grade: Automatic

Voltage: 110V/220V

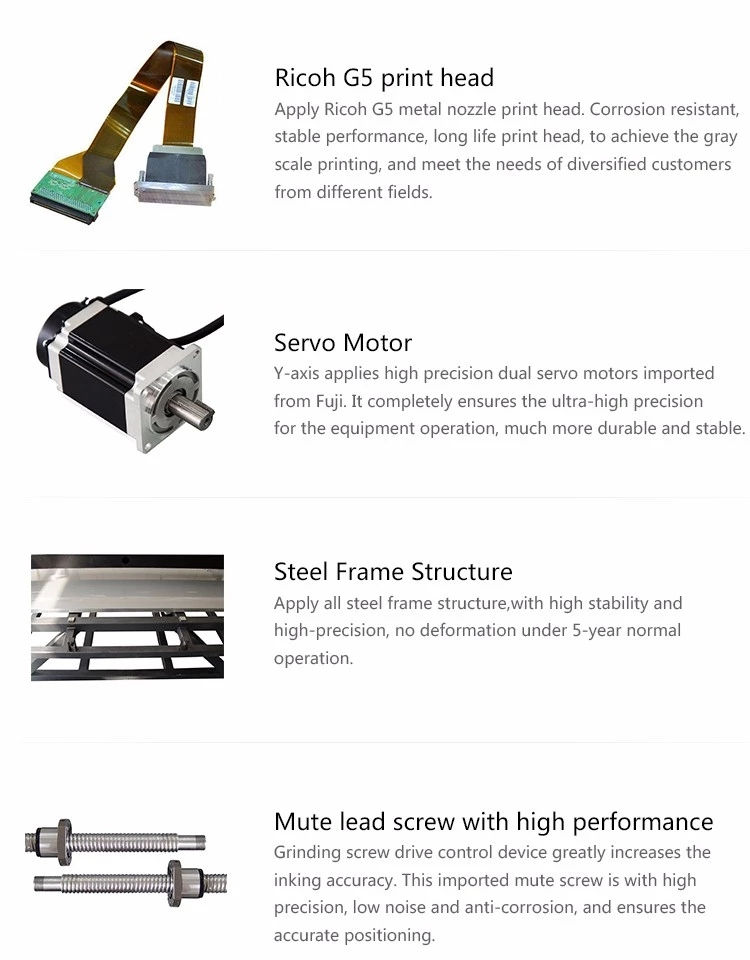

Print head: Ricoh Gen5

Print speed: 12-80sqm/h

Printing height: 100mm

Ink Volume: 3500ml

RIP Software: ColorGATE RIP9(FREE)

Print Interface: High Speed USB transfer 3.0 interface

Type: Digital Printer

After-sales Service Provided: Engineers available to service machinery overseas

Product Description

| Model Type | 1612 | 2513 | DLI 2030 |

| Max Printing Size | 1600 X 1200MM | 2500 X 1300MM | 2000 X 3000MM |

| Equipment Weight | 1200kg | 1500kg | 1800kg |

| Print Head | Ricoh Gen 5 industrial head | ||

| Print Color | CMYK+White;Double CMYK;CMYK+lc+lm+ly+lk; | ||

| Print Height | Up to 100MM(customized up to 400MM) | ||

| Print Precision | 720*900DPI/720*1200DPI/720*1800DPI | ||

| Lifting Function | Intelligent Ink Tank Lifting, Electric-Automatic Or Manual. | ||

| File Format | TIFF(RGB&CMYK),BMP,PDF,EPS,JPEG... | ||

| Print Speed | Double 4 Color is up to 75 sqm/h High speed mode:26 sqm/h (4 PASS Bi-direction) | ||

| Ink Volume | Continuous ink supply/Max capacity 2000ml | ||

| Power | AC220/110±10,50HZ~60HZ,P 4500W | ||

| Driver Software | Microsoft Windows7 x64 | ||

| RIP Software | GermanColorGATE RIP9/ Photo Print | ||

| Operating Environment | Temperature 20℃~32℃,Humidity 40~70% | ||

| Equipment dimension | 3430mm*1970mm*1325mm(L/W/H) | 4230mm*2070mm*1325mm | 3730mm |

| Package dimension | 3530mm*2070mm*1582mm(L/W/H) | 4500mm*2200mm*1582mm | 3830mm |

Equipment Details

| High quality Configuration | Explain |

| 3 servo motors (2 for Y axis;1 for X axis) | The crossbeam is made of high quality and durable steel. After annealing treatment, it is guaranteed not to deform within 3 years, and the deformation can be controlled within 5 years. That is,the service life of the equipment can be extended. |

| Vacumm system support points up to 39 | Dlican underframe with 39 adjustment support points. So the platform precision is higher. |

| 12 route suction points | The base of the platform adopts the 12 - way suction hole.The negative pressure area of the suction hole is more uniform. |

| All steel body | The whole steel structure. After annealing treatment, The structure is stable and not deformed. |

| The thickness of steel is 5mm | 5mm thickness square tube to ensure the stability |

| 45mm thickness aluminium vacumm platfor | To avoid being squeezed out of shape during transportation |

| stainless steel guide screw and linear guide | Double lead screws |

| Japanese imported negative pressure display | High precision negative pressure display, 0.1kpa adjustment accuracy. |

| Eletrostatic system | Optional function |

| Independent press ink control system | Each color controlled independently which help save 15 volume ink |

| Automatic ink temperature control system | Fully automatic temperature control system, precise control temperature, ensure that ink reaches the best viscosity and performance before entering the nozzle. |

| Automatic height measurement, colliation prevention and anti rubbing system | Optional function |

| Secondary ink Thermostatic heating system | Secondary ink Thermostatic heating system to solve ink flow in various low temperature conditions. |

| Negative pressure overload protection device | Protect swirl fan not racing, which to avoid a damage of the vacumming platform that has been fully covered by printing medium. |

| ink multistage liquid level sensor | Independant ink volume display |

| Oxidation treatment of head floor | Reduce the refraction of UV fiber and protect the print heads |

| Vertical adjustment device for nozzle seat | Convenient for the customer to finish the color correction and keep the printing precision |

Highlights

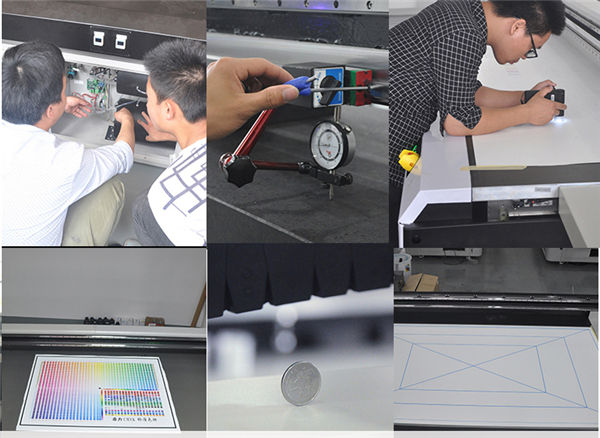

Our Services

Warranty: 12 months. When the warranty expired, technician support is still offered. Hence we offer lifelong after-sale service.

Print service: We can offer you free samples and free sample printing

Training service: We offer 3-5 days free training with free accommodations in our factory, including how to use the software, how to operate

the machine, how to keep daily maintenance, and useful printing technologies, etc.

Installation service: On-line support for installation and operation. You can discuss operation and maintenance with our technician online

support service by Skype, Wechat etc.Engineers available to service machinery overseas.

Meanwhile, engineers intall at overseas available.

Company Information

Quality is our first choice and we are committed to deliver best quality products to our customers!